Product_Name: Multi-disc Sludge Dewatering Screw Press Machine

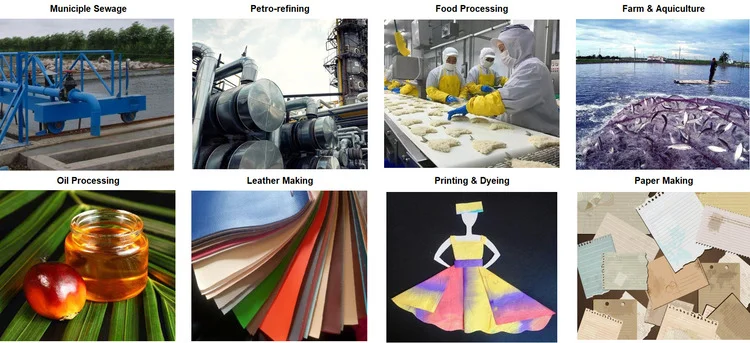

Details:Screw sludge dewatering machine is designed to handle a wide range of sludge, especially sludge containing high oil and fat which easily stick to dewatering parts. Excellent performance has been proved in but no limited to the following industries.

● Municipal sludges from WWTP, including aerobic and digested

● Slaughterhouse sludges from DAF

● Textile sludges, such as dyeing and painting

● Food processing wash-down biological sludges, including dairy, beer, beans etc.

● Oily wash-down, including oil tank, fuel tank, car wash

● Pharmacy waste

● Printing oily ink waste

Click Photos below to see application reference.

Screw sludge dewatering machine technical advantages

●Force water concurrent:

The force and water work in the same direction to make the free water separated with the fastest speed

●Moderate pressure:

Mantain the lowest energy consumption and mechanical wear while ensuring the sludge dewatering effective

●Thin-layer dewatering:

Dewatering with thin layer makes the free water separated with the fastest speed

●Extension the dewatering path:

To allow enough time and continuous operation in dewatering

●Power Saving:

less than 5%of centrifuge

●Program Control:

24-hour unattended automatic operation

●Water Saving:

less than 0.1%of belt filter press

●Flexible Feed Sludge:

solid concentration from <0.2%to >4%

●No clogging:

for high oil and fat content sludges

●Low Running Speed, Vibration Noise:

less abrasion thus long-life span

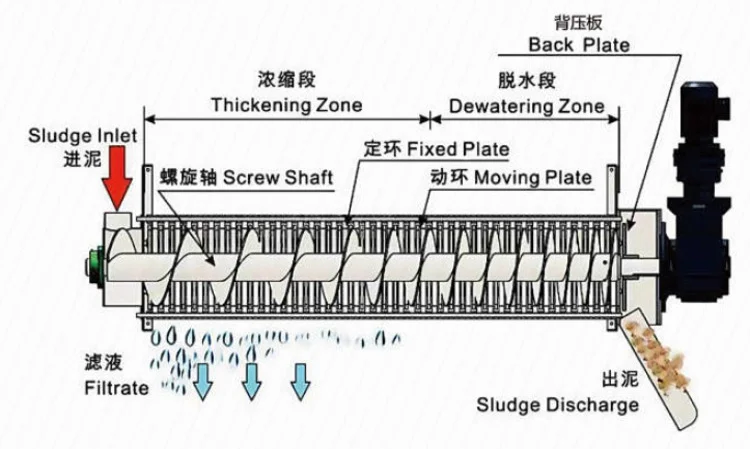

The sewage slurry feeds intomixing and flocculating tanks, withPAC/PAM added, flocculated to groups. Flocculated sludge flows intoscrew press, through the mutual movement ofscrew shaft, fixed rings,moving rings andbackplate, free water is pressed out to realize dewatering. In thickening zone, most of free water is separated, and then when sludge is pushed todewatering zone, gaps between screw shaft and rings become smaller, pressure increased, 2nd section separation completed. Separated water falls tocollecting base and dried mud cake falls from sludge outletfor transporting outside by truck or stored.